Hintergrundinformationen zu den Crashtests

Dies waren einige der wichtigsten Fragen, die wir uns bei IXTAbox stellten, bevor wir Crashtests am Schwedischen Nationalen Straßen- und Transportforschungsinstitut in Linköping (VTI) durchführten:

- Wie gut schlägt sich eine IXTAbox in einer Crash-Situation?

- Was kann eine schwer beladene IXTAbox bei einem Crash aushalten?

- Was passiert bei einem Unfall? – Löst sich die Anhängerkupplung? – Öffnet sich der Deckel?

- Was geschieht mit Gegenständen, die auf dem Deckel geladen werden?

- Wie schneidet eine IXTAbox im Vergleich zu einer Marken-Dachbox auf dem Markt ab?

- Wie schwerwiegende Abstürze kann eine IXTAbox im Vergleich zu anderen getesteten Produkten überstehen?

- Welche Anforderungen werden aus Crash-Sicht an eine am Heck montierte Ladebox gestellt?

- Welche weiteren Anforderungen müssen für den Verkauf einer rückseitig montierten Box erfüllt sein?

Im Herbst 2024 und Anfang 2025 führte Prodelox AB im Auftrag und in Zusammenarbeit mit IXTAbox Beratungsarbeiten durch, um etwaige regulatorische Anforderungen oder Normen zu ermitteln, die für rückseitig montierte Boxen gelten.

Die Studie kam zu dem Schluss, dass es für diese Art von Produkt keine verbindlichen Anforderungen oder spezifischen Normen (einschließlich Crashnormen) gibt, mit Ausnahme von Beleuchtungsanforderungen und möglicherweise der ECE R 26-Vorschriften in Bezug auf scharfe Kanten und die Gefahr von hervorstehenden Teilen, an denen sich gefährdete Verkehrsteilnehmer verfangen könnten.

Die schwedische Transportbehörde Transportstyrelsen beauftragte VTI mit der Prüfung der Konformität der IXTAbox mit den ECE-R-26-Vorschriften. VTI bestätigte, dass keine zugänglichen scharfen Kanten oder gefährlichen hervorstehenden Teile vorhanden sind. VTI ist der Ansicht, dass die IXTAbox alle Anforderungen der ECE-R-26 erfüllt. Die Zertifizierung wurde jedoch noch nicht offiziell beantragt.

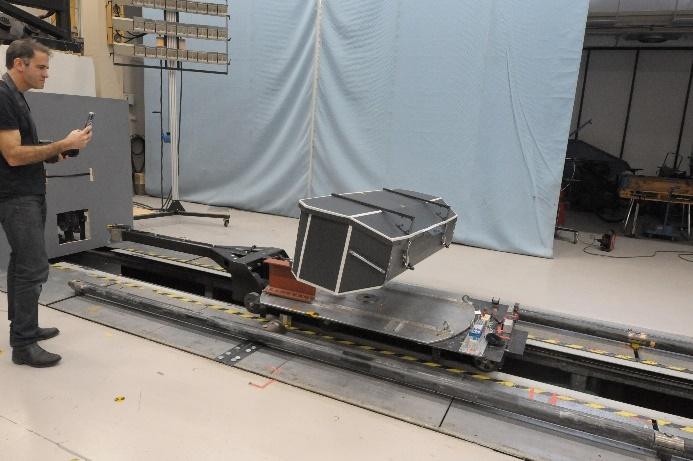

Mit diesem Wissen im Gepäck führten wir Gespräche mit sachkundigen Mitarbeitern von VTI, um eine geeignete Reihe von Crashtests zu entwerfen, mit dem Ziel, die Funktion und Sicherheit des Produkts auf der Grundlage etablierter Crashtest-Standards zu überprüfen.

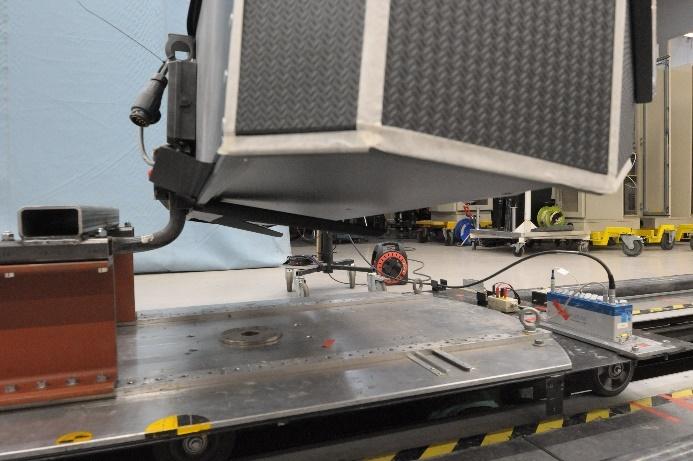

Zur Validierung der IXTAbox und zur Beantwortung der oben genannten Fragen wurden insgesamt sechs Crashtests durchgeführt: fünf mit der IXTAbox und ein Referenztest mit einer Dachbox. Der Crashtest mit der IXTAbox fand am 25. Februar 2025 statt.

Bedingungen für die Crashtests

Die zulässige maximale Stützlast für einen Anhänger beträgt üblicherweise 100 kg. Die getestete IXTAbox wog 34 kg, was bedeutet, dass sie theoretisch mit 66 kg beladen werden konnte. Stattdessen wurde sie mit 75 kg Holz, Faserplatten und Skiausrüstung beladen – eine leichte, aber bewusste Überladung. Die Form der Platten gewährleistete eine gleichmäßige Gewichtsverteilung über die gesamte Breite der IXTAbox.

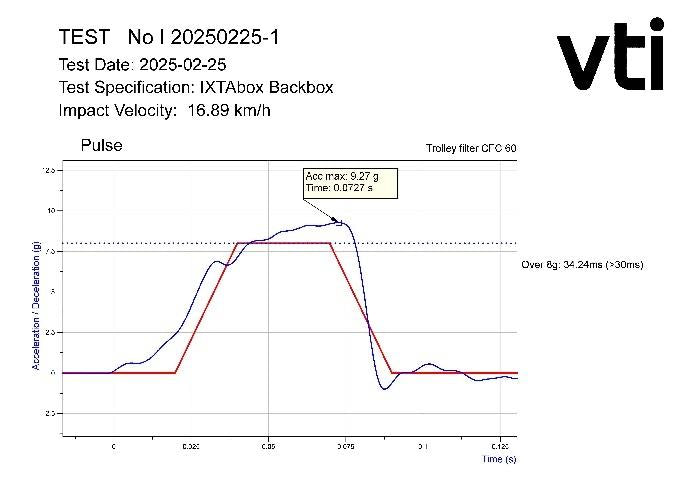

Crashtest 1

Verwendetes Prüfverfahren: Norm für Dachlasten/Dachboxen SS-ISO 11154:2023

Dieser Test beinhaltet einen Aufprall mit 16 km/h (Toleranz: -0 / +2 km/h) und einer Beschleunigung von über 8 g für mindestens 30 ms. Es dürfen sich maximal 10 Gramm Last oder Bauteile lösen.

- Geschwindigkeit: 16,89 km/h

- Dauer über 8 g: 34,24 ms

- Maximale g-Kraft: 9,27 g

Crashtest 1 Galerie

Kurve, die die Beschleunigung während des Tests 2025-02-25—1 zeigt. Die Bilder zeigen die auf der Anhängerkupplung montierte IXTAbox mit Testlast und den Zustand der Box nach dem Crashtest.

Ergebnisse von Test 1

Es hatten sich keine Teile gelöst. Der Kasten blieb unbeschädigt. Lediglich eine geringfügige Winkelverschiebung an der Anhängerkupplung wurde festgestellt.

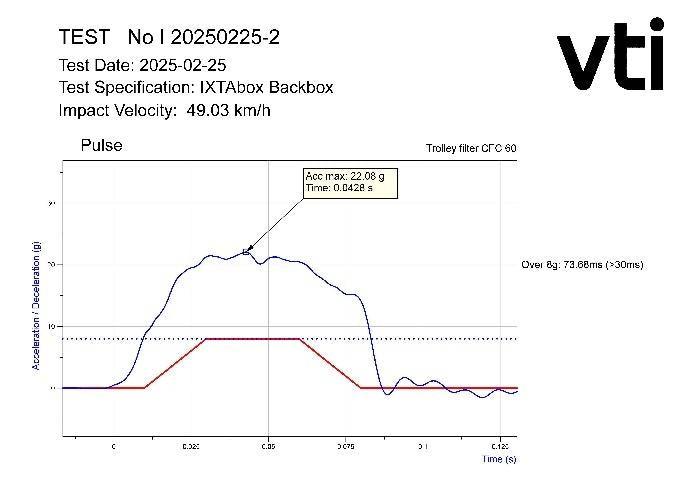

Crashtest 2

Auf Grundlage der Ergebnisse von Test 1 wurde im nächsten Test ein intensiverer Aufprallimpuls verwendet, ähnlich dem für Kindersitze (Normen wie ECE R 17 und ECE R 129):

- Geschwindigkeit: 49 km/h (Toleranz für 50 km/h: -2 / +0 km/h)

- Verzögerungsstrecke: 550–600 mm

- Ziel: 20 g für mindestens 15 ms überschreiten

- Maximale g-Kraft: 22 g

Ergebnisse von Test 2

Über 20 g für ca. 34 ms. Die IXTAbox blieb intakt, mit nur einer leichten Vorwärtsneigung. Es wurde keine Last freigesetzt.

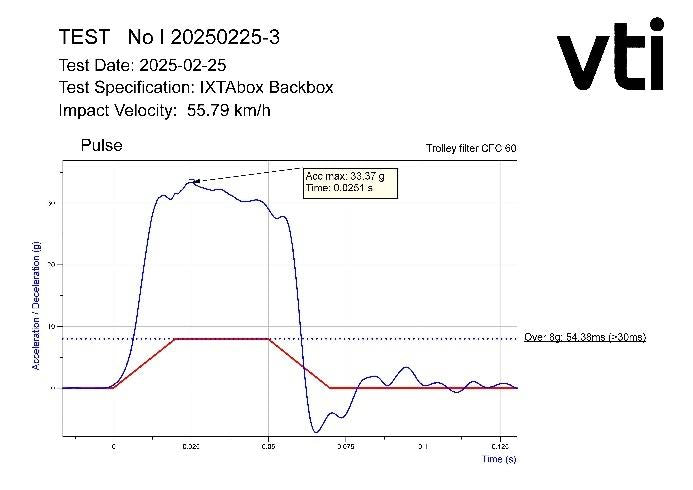

Crashtest 3

Aktuell wird mit dem „Plus-Impuls“ getestet, einem härteren Crashtest, der für Kindersitze zur Erlangung der „Plus“-Zertifizierung eingesetzt wird. Obwohl diese Standards nicht direkt auf Dachboxen übertragbar sind, ist die hohe Belastung für die Validierung im Verbraucherbereich hilfreich. Hierbei ist zu betonen, dass es auch darum geht, niedrige Belastungswerte für die verwendete Kinder-Crash-Puppe zu erzielen. Daher lassen sich die umfangreichen Anforderungen an Kindersitze nicht direkt auf Anforderungen an Dachboxen übertragen.

- Geschwindigkeit: 56 km/h

- Verzögerung: 470–490 mm

- Maximale g-Kraft: 33,4 g

- Über 30 g für mehr als 30 ms (4x höher als ISO 11154:2023)

Crash Test 3 Galerie

Kurve, die die Beschleunigung während des Tests 2025-02-25—3 darstellt. Die Bilder zeigen die während des Tests verursachte Verformung.

Ergebnisse von Test 3

Es ist erwähnenswert, dass in den Tests 1 und 2 dieselbe Box verwendet wurde und dass die IXTAbox in Test 3 leichte Beschädigungen erlitt. Einige Nieten am Boden der IXTAbox hatten sich gelöst. Der Deckel wies geringfügige Verformungen auf. Es wurden keine Teile oder Ladung ausgestoßen.

Die Schachtel erfüllte formal noch immer die Norm, dass sich kein Gegenstand mit einem Gewicht von über 10 Gramm lösen durfte.

Crashtest 4

Aufgrund einer Teilbeschädigung im Test 3 wurde eine neue IXTAbox verwendet.

- Auf dem Deckel der Kiste waren ein Damenfahrrad mit Gepäckträger (ca. 23 kg) montiert.

- Die interne Last wurde auf 52 kg eingestellt.

- Der Test erfolgte gemäß ISO 11154 bei 17 km/h und ca. 8–10 g.

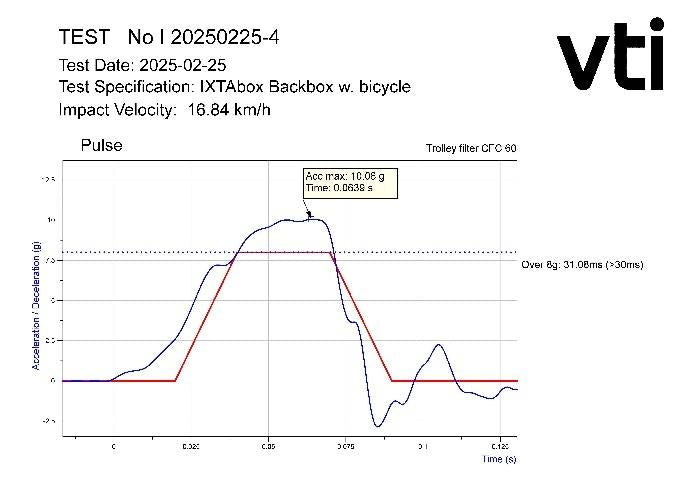

Crash Test 4 Galerie

Kurve, die die Beschleunigung während des Tests 2025-02-25—4 zeigt. IXTAbox vor dem Test, beladen mit Fahrrad und Fahrradträger.

Ergebnisse von Test 4

Der höhere Schwerpunkt führte dazu, dass das Fahrrad leicht nach vorne kippte. Eine der Streben riss leicht ein, aber es löste sich nichts.

Die ISO-Anforderung wurde weiterhin erfüllt.

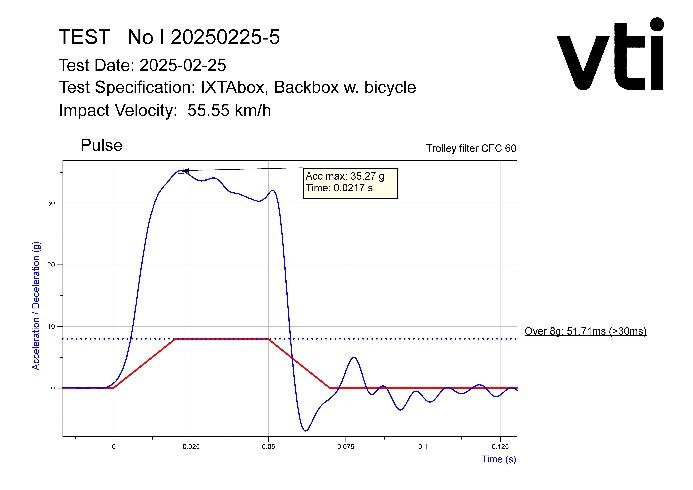

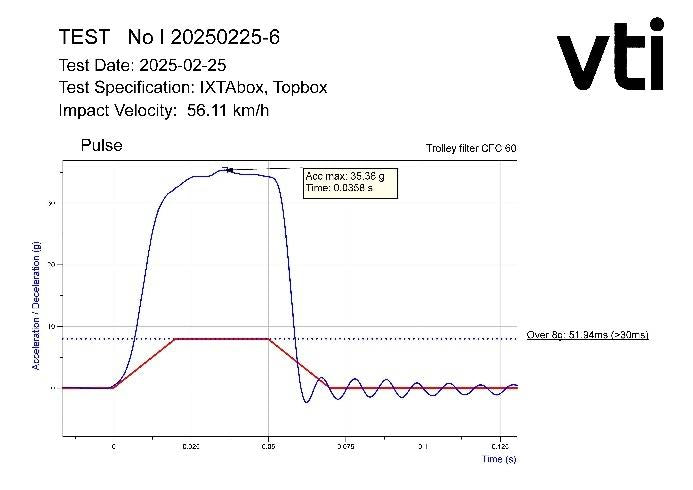

Crashtest 5

Das extremste Szenario: Plus Pulse mit dem 23 kg schweren Fahrrad oben drauf und 52 kg im Inneren.

- Die Box aus Test 4 wurde repariert (nur die Schiene wurde ausgetauscht).

- Geschwindigkeit: 56 km/h

- Verzögerung: 470–490 mm

- Maximale g-Kraft: 35,3 g, davon über 30 g für 39 ms

Ergebnisse von Test 5

Das Fahrrad blieb zwar befestigt, neigte sich aber stärker, und am Boden der Box war ein größerer Riss zu sehen, wobei einige Nieten abgerissen waren. Es trat nichts aus. Die IXTAbox blieb an der Anhängerkupplung befestigt (die sich verformt hatte).

Ein harter Test, aber die Box hat sich beeindruckend geschlagen.

Zusammenfassung der ersten 5 Crashtests

IXTAbox übertrifft die Anforderungen der ISO 11154:2023, selbst wenn:

- Beladen mit 75 kg

- Ein Fahrrad oben drauf tragen

- Sie waren Aufprallkräften ausgesetzt, die weit über die Anforderungen an Dachboxen hinausgingen.

Die Ergebnisse lassen vermuten, dass IXTAbox künftige Crashnormen für Heckboxen erfüllen oder sogar übertreffen könnte.

Die Konstruktion aus Aluminium und Edelstahl absorbiert effektiv die Aufprallenergie und verhindert so sowohl das Ablösen von der Anhängerkupplung als auch das Herausfallen der Ladung.

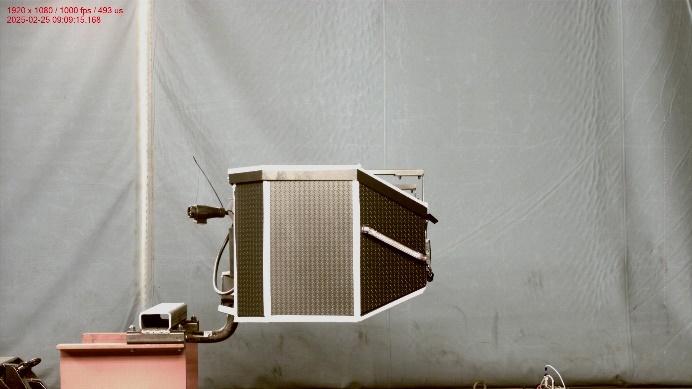

Crashtest 6 – Dachbox-Referenztest

Ziel: Testen, wie eine herkömmliche Dachbox einer führenden Marke mit dem gleichen Plus-Impuls (56 km/h, ~33–35 g) umgeht.

- Eine mit 75 kg beladene Dachbox wurde auf einem Marken-Dachträger montiert, der auf von VTI hergestellten, simulierten Dachrelingen befestigt war.

- Der Dachgepäckträger wurde unter Verwendung eines Drehmomentbegrenzungswerkzeugs, das auf 4 Nm eingestellt war, montiert.

Ergebnisse

Durch ein Missgeschick rutschte der Dachgepäckträger auf den Schienen, was Folgendes zur Folge hatte:

- Die Dachbox bewegt sich nach vorne in die Bremsbarriere.

- Die Schachtel öffnet sich und ihr Inhalt tritt teilweise aus.

Dies beeinträchtigte die Aussagekraft des Tests, da das Ergebnis eher die Grenzen des Dachgepäckträgers als die Box selbst widerspiegelt.

VTI merkte an, dass wahrscheinlich kein herkömmlicher Dachträger einer solch extremen Verzögerung standhalten kann. Es besteht ein erhebliches Risiko, dass sich Dachboxen bei einem realen Unfall mit diesen Geschwindigkeiten vollständig lösen und ihren Inhalt wie Geschosse herausschleudern.

Kurve, die die Beschleunigung während des Tests 2025-02-25—6 zeigt.

VTI merkte an, dass wahrscheinlich kein typischer Dachgepäckträger einer solch extremen Verzögerung standhalten kann.

Bei diesen Geschwindigkeiten besteht ein erhebliches Risiko, dass sich Dachboxen bei einem realen Unfall vollständig lösen und ihren Inhalt wie Geschosse herausschleudern.

Gesamtergebnisse der Crashtests

VTI-Bewertung

Die IXTAbox wurde anhand der anwendbaren Abschnitte von ISO 11154:2023, ECE R 17, ECE R 129 und ECE R 26 geprüft und bewertet. Da die IXTAbox weder ein Dachgepäckträger noch ein Fahrzeug ist, kann sie nach diesen Methoden nicht formell "zugelassen" werden, sie erfüllt oder übertrifft jedoch alle angewandten Schwellenwerte und Testverfahren.

Unsere Reflexionen bei IXTAbox

Wir sind stolz darauf, dass IXTAbox die Tests so gut bestanden hat. Wir können beruhigt schlafen, da wir wissen, dass es sich wahrscheinlich um eine der sichersten Transportlösungen für Pkw auf dem Markt handelt.

Wir sind überrascht und etwas besorgt darüber, dass die formalen Anforderungen an Dachboxen so niedrig angesetzt sind. Von ihnen lediglich eine Widerstandsfähigkeit bei einem Aufprall mit 17 km/h zu erwarten, erscheint unzureichend, insbesondere wenn man bedenkt, dass die meisten Menschen auf dem Weg zu oder von Bergtouren deutlich über 50 km/h fahren.